Hydraulic machinery often operates in extreme temperatures that impact performance; however, this factor is frequently overlooked when selecting products, leading to reduced efficiency and reliability.

Ambient temperatures have considerable influences of the safety, functionality, and reliability of a hydraulic system. Significantly hotter temperatures lessen the viscosity of the hydraulic fluid making the oil thinner, whereas significantly colder temperatures will increase viscosity, making it hydraulic fluid thicker.

What does this mean for your hydraulic system?

Premature failure and damage to your hydraulic system. Using the incorrect hoses and fitting for extreme applications will cause extensive damage to your assets, reduce performance, and may cause serious injury to operators or by standers. It is vital to fit equipment with temperature regulated products to ensure longevity.

Hydraulics Operating in Low Temperatures

Extreme Cold Hydraulic Application

Long term exposure to extremely cold climates can significantly alter the flexibility of a hydraulic hose and movement of the fluid. This results in premature cracking, fracturing, and splitting in the hose.

Additionally, such temperatures will have considerable damage to other rubber components which make up the hose assembly. These components can be O-Ring seals; tube clamps, and mounts made of thermoplastic polymer.

Hydraulics Operating in High Temperatures

Hydraulic systems exposed to significantly hot temperatures has the potential to opposite effect to exposure to cooler climate conditions.

Extreme Hot Hydraulic Application

When the hydraulic system experiences extreme heat performance of the system diminishes as the fluid becomes thinner and can cause the fluid to weep and seep through the hose fitting. This can also cause extreme oxidation within the fluid transfer system. As a result, there can be higher levels of premature wear on the internal hose complementary.

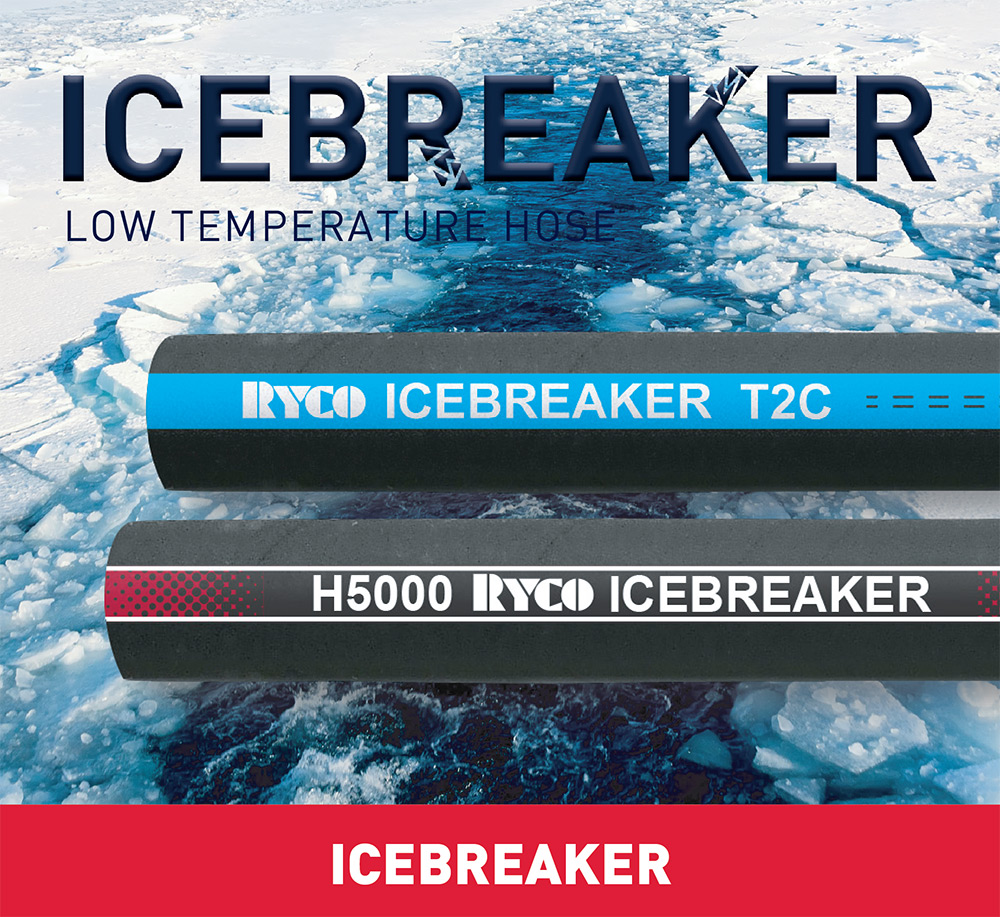

Solutions to Extreme Cold Operating Temperatures – Ryco ICEBREAKER

Preparing your hydraulic machinery for icy and cooler temperatures begins with selecting the correct hose range for the application.

Choosing the Ryco ICEBREAKER hose will ensure hydraulic machinery is operating at an optimum level in extremely colder temperatures. The Ryco ICEBREAKER range can operate efficiently from -60°C to +100°C (-76°F to +212°F).

Ryco ICEBREAKER Hose Range

This hose range boasts a maximum working pressure that is based on a 4:1 safety factor (maximum working pressure to minimum working pressure).

Ryco ICEBREAKER hoses are recommended for high pressure hydraulic oil applications where low temperature environmental conditions exist.

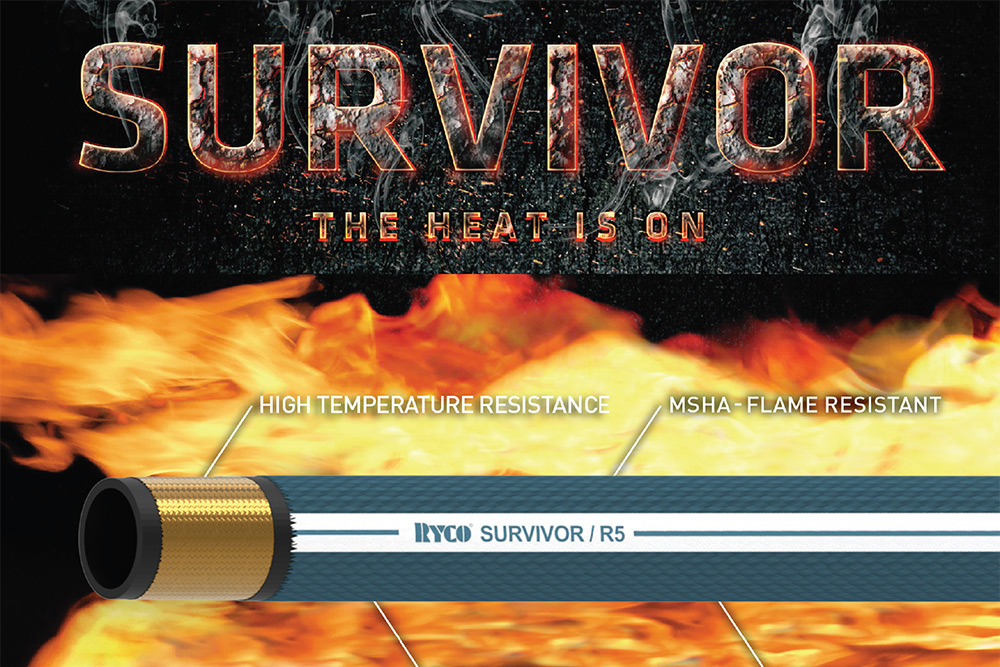

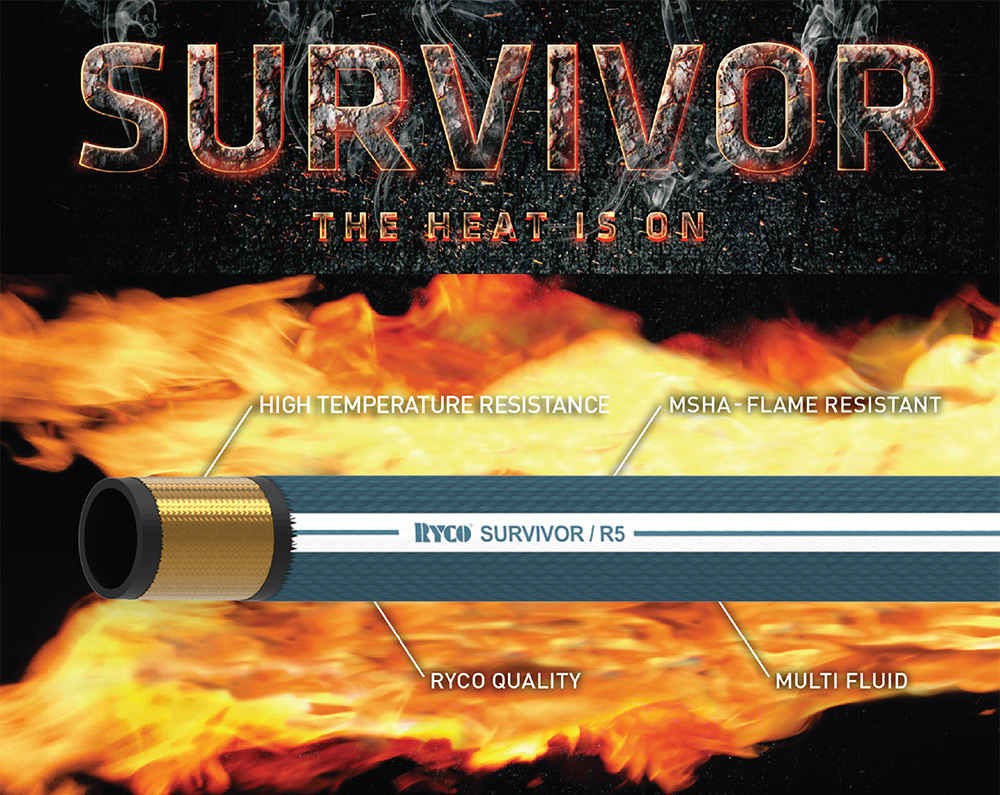

Solution to Extreme Hot Operating Temperatures – Ryco SURVIVOR

Preparing your hydraulic machinery for extremely hot climates also begins with selecting the correct hose range for the application. Choosing the Ryco SURVIVOR hose will ensure hydraulic fluid is protected from losing viscosity and extensive wear on the hose system.

As part of our commitment to continuous improvement, Ryco has upgraded the hose family – SURVIVOR, intended as direct improvement to the previous RQP specialty and high temperature hose range.

The Ryco SURVIVOR range can operate efficiently from rom -46°C to +135°C (-50°F to +25°F); Peaks of 150°C (300°F).

Ryco SURVIVOR Hose Range

As part of our commitment to continuous improvement, Ryco has upgraded the SURVIVOR range, intended as direct improvement to the previous RQP specialty and high temperature hose range.

This range boasts a maximum working pressure based on 4:1 safety factor (maximum working pressure to minimum burst pressure).

For further information about selecting the correct hose and fittings for extreme temperatures, please contact us..