JIS Threads

Japanese Industrial Standards (JIS) Threads

JIS Threads

| JIS | Japanese Industrial Standards | There are four popular couplings styles in Japan. |

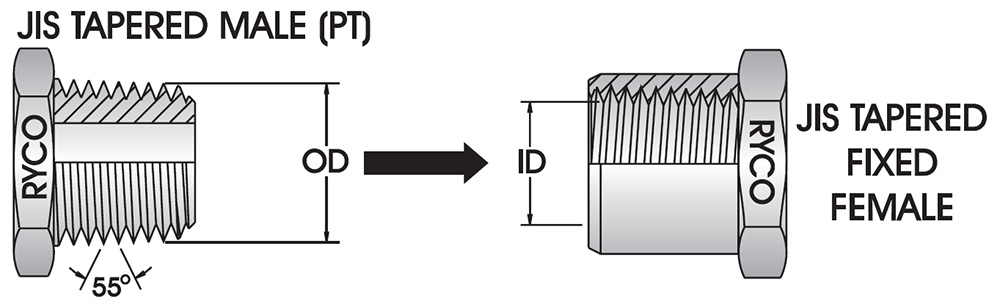

1. JIS Tapered

Pipe Thread

The Japanese tapered pipe thread connector is identical to and interchangeable with the BSPT (tapered) connector. The Japanese male thread does not have a 30° Flare, and will not mate with the BSPP female swivel with conical seat.

The seal on the Japanese tapered pipe thread connector is made on the threads. Use of a thread sealant is recommended.

The seal on the Japanese tapered pipe thread connector is made on the threads. Use of a thread sealant is recommended.

Thread form per JIS B 0203 (identical to BSPT)

Refer to BSPT section for dimensions of threads.

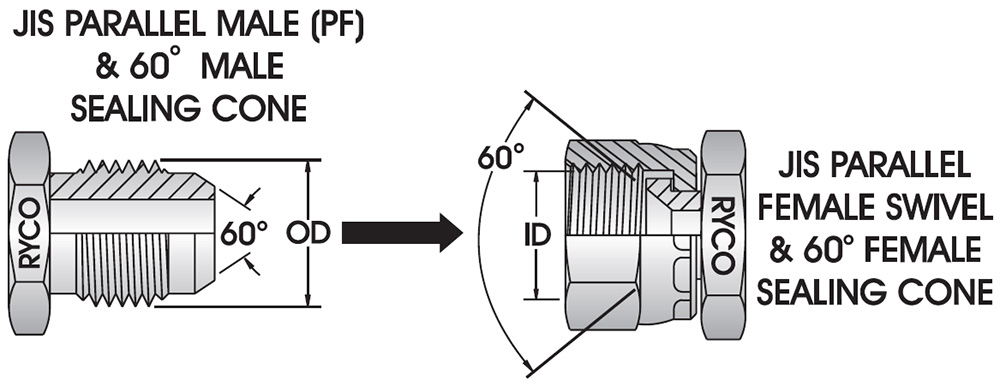

2. JIS 30° Flare

(Female Internal Cone Seat)

This connection uses a 60° concave (inverted) seat and British Standard Pipe Parallel threads. They are not interchangeable with BSPP conical seat couplings, because the cone seats are opposite.

Thread form per JIS B 0202 (identical to BSPP)

Refer to BSPT section for dimensions of threads.

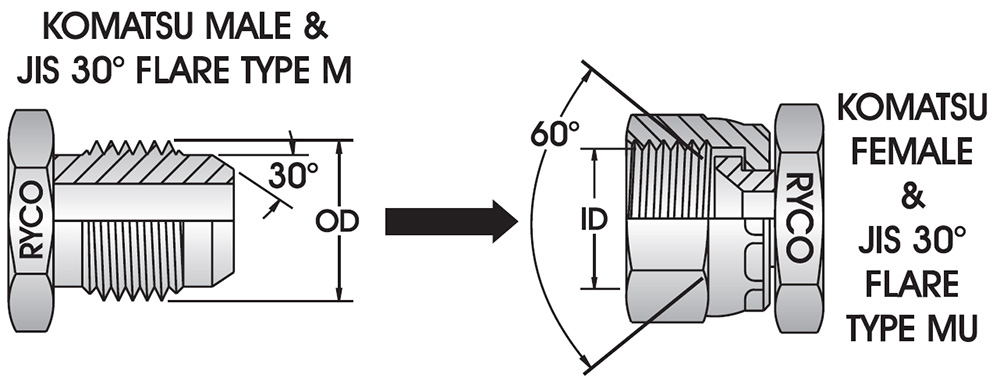

3. Komatsu 30° flare (Female Internal Cone Seat)

Threads commonly used on Komatsu equipment (30° cone) have metric thread form.

| MALE THREAD OD & PITCH |

DASH SIZE |

FEMALE THREAD ID |

|---|---|---|

| mm | mm | |

| M14 x 1,5 | -1415 | 12,5 |

| M18 x 1,5 | -1815 | 16,5 |

| M22 x 1,5 | -2215 | 20,5 |

| M24 x 1,5 | -2415 | 22,5 |

| M30 x 1,5 | -3015 | 28,5 |

| M33 x 1,5 | -3315 | 31,5 |

| M36 x 1,5 | -3615 | 34,5 |

| M33 x 1,5 | -3315 | 31,5 |

4. Komatsu Style Flange Fitting JIS B 8363

The Komatsu style Flange fitting is nearly identical to, and fully interchangeable with, the SAE Code 61 flange fitting*. The O Ring dimensions are different between all sizes. When replacing a Komatsu style flange with an SAE style flange, an SAE style O Ring must always be used. *5/8” is not in the SAE Standards.

BSPT & BSPP Threads Dimensions

| BSPT & BSPP SIZE & PITCH |

DASH SIZE |

BSPT MALE THREAD OD |

BSPP MALE THREAD OD |

BSPT FEMALE THREAD ID | BSPP FEMALE THREAD ID |

||||

|---|---|---|---|---|---|---|---|---|---|

| inch – TPI | mm | inch | mm | inch | mm | inch | mm | inch | |

| 1/8 – 28 | -02 | 9,5 | 0.37 | 9,6 | 0.38 | 8,4 | 0.33 | 8,6 | 0.34 |

| 1/4 – 19 | -04 | 12,8 | 0.50 | 13,0 | 0.51 | 11,2 | 0.44 | 11,9 | 0.47 |

| 3/8 – 19 | -06 | 16,3 | 0.64 | 16,5 | 0.65 | 14,7 | 0.59 | 15,2 | 0.60 |

| 1/2 – 14 | -08 | 20,4 | 0.80 | 20,8 | 0.82 | 18,3 | 0.72 | 19,1 | 0.75 |

| 5/8 – 14 | -10 | 22,5 | 0.89 | 22,8 | 0.90 | 20,6 | 0.81 | 20,8 | 0.82 |

| 3/4 – 14 | -12 | 25,9 | 1.02 | 26,3 | 1.04 | 23,9 | 0.94 | 24,6 | 0.97 |

| 1 – 11 | -16 | 32,6 | 1.28 | 33,1 | 1.30 | 29,7 | 1.17 | 30,7 | 1.21 |

| 1.1/4 – 11 | -20 | 41,1 | 1.62 | 41,8 | 1.64 | 38,6 | 1.52 | 39,4 | 1.55 |

| 1.1/2 – 11 | -24 | 47,0 | 1.85 | 47,7 | 1.88 | 44,5 | 1.75 | 45,5 | 1.79 |

| 2 -11 | -32 | 58,6 | 2.31 | 59,5 | 2.34 | 56,4 | 2.22 | 57,4 | 2.26 |

| 2.1/2 – 11 | -40 | 74,1 | 2.92 | 75,1 | 2.95 | 71,9 | 2.83 | 72,6 | 2.86 |

| 3 – 11 | -48 | 86,6 | 3.41 | 87,9 | 3.46 | 84,6 | 3.33 | 85,4 | 3.36 |